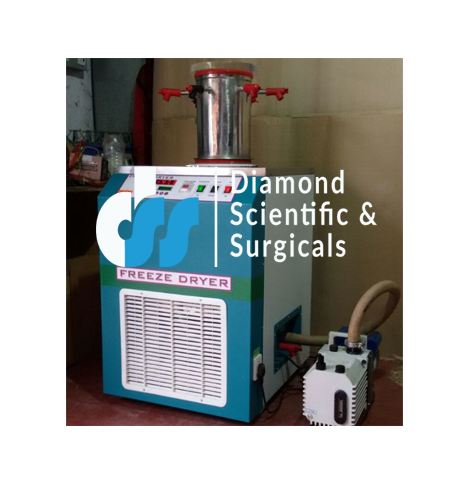

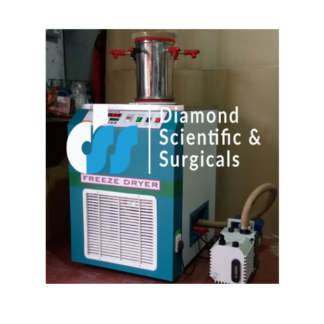

Freeze Dryer (Freeze dryer or lyophilizer for pharmaceutical laboratory)

Description

APPLICATION ADVANTAGE

Heat sensitive biological materials may be freeze-dried without affecting their potency. The dried materials may be stored for years at room temperature without loss of their original characteristics.

The freeze-dried material may be transported and shipped in small containers, and no provision is necessary for refrigeration enrooted.

Bacterial growth and enzyme action do not take place in freeze-dried products and proteins do not coagulate.

Oxidation of many materials such as haemoglobin and vaccines is completely prevented when drying and sealing is done under high vacuum.

WHAT IS FREEZE DRYING?

Freeze drying is the process of removing the moisture from a biological product while maintaining the integrity of the biological products, chemical structure and activities. Freeze drying technology is used in particular for removal of moisture from the products usually of biological origin without causing any noticeable change in the original characteristics. Freeze drying is also the preferred process in the field of Pharmacy, Chemistry and in conservation of Food.

HOW FREEZE DRYER WORKS:

All “APS” units are provided with following basic requirements:-

A Drying Chamber or Manifold on/in which the containers with pre-frozen samples are connected/placed.

A high Vacuum double stage pumping system with gas ballast with ultimate vacuum of less than 50 microns in the system and 10 microns on pump head to facilitate the vapour flow to the condenser for speedy drying.

A low temp. Condenser to trap the moisture vapour and allow the non- condensable vapours to go to the pump for release to the atmosphere.

CONSTRUCTION & SALIENT FEATURES

Housed in a super structure steel frame it is mounted on swivel casters.

Complete with Perspex see through lid, gasket and control instruments i.e. Microprocessor Based Digital Temperature Controller for measurement of Temp. & Electronic digital Vacuum Indicator.

The unit made out of hermetically sealed compressor and can be optionally fitted with 100 litters/ min direct motor drive rotary vane type vacuum pump of double stage with Air ballast having ultimate vacuum of 1×10-3 torr on pump head.

High grade PUF INSULATED between outer and inner chamber for minimal thermal losses.

Condenser Trap: All non-magnetic stainless steel fabricated, argon welded, dished-bottom for complete effluent removal.

Refrigeration coils made of copper bonded to outside of condenser heavily insulated. Temp. up to (-)400 C at ambient temperature of 200 C is maintained through a MICROPROCESSOR BASED DIGITAL TEMPERATURE INDICATOR – CUM – CONTROLLER.

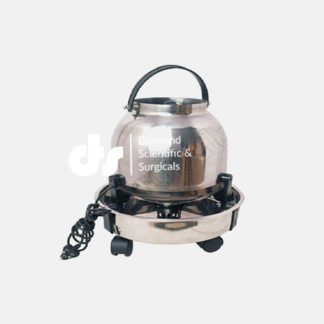

Vacuum Drum has 6 or 12 port manifold (Main drying chamber) made of stainless steel non-magnetic grade with Perspex top cover. (CFC FREE AND PUFF INSULATED).

TECHNICAL SPECIFICATIONS & ORDERING INFORMATIONS

Capacity

3.25 Liters

Vacuum Drying Drum Size

22.5cm (dia) x 25.5cm (ht)

MOC (Body)

CRC duly powder coated on caster wheels.

MOC (Main Drying Chamber)

Stainless Steel (Non Magnetic)

Temperature Range

Up to -400C (at ambient temperature of 200C)

Controller

Microprocessor Based Digital Temperature Controller

Vacuum Probe

Electric vacuum transducer

Vacuum Indicator

Digital vacuum indicator

Vacuum Seals

CRC duly powder coated on caster wheels.

Ultra Ultimate Vacuum (Pump Head)

1 x 10-3 torr

No. of Drying Ports 6

Heat Rack (Option)

(Tray, Petri Dishes, Beakers etc) (Adoptable to the main drying chamber)

Vacuum Pump (Option)

100 litters/ min direct motor drive rotary vane type vacuum pump of double stage

with Air ballast having ultimate vacuum of 1×10-3 torr on pump head

High Voltage Protection (Option)

Through automatic voltage stabilizer

Reviews

There are no reviews yet.